Overview

Stainless Steel KF Vacuum Flange

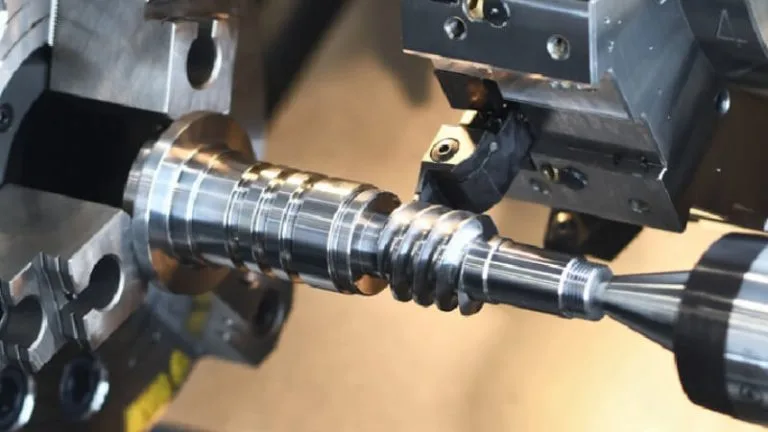

Stainless Steel KF Vacuum Flange is a component or assembly manufactured by machining. Stainless steel is a hard and viscous material. Regarding processing complexity, it is about three times superior to softer metals, like aluminum. This means that to make a part from stainless steel, the machine must make three times as many passes. And the tool, which performs processing, wears out faster. But this is not a problem for us.

The ISO-KF system is a modular, building block method of creating a piping system. There are several advantages to the use of Stainless Steel KF Vacuum Flange. Since component dimensions are standardized, elbows, tees, crosses, or valves for a given size may be interchanged. These KF-50 90-degree elbow vacuum fittings follow ISO-KF standards and have a flange size of NW-50. They are commonly used to build fireline vacuum plumbing and process systems. They are often called quick flange fittings because they are quick to assemble. A circumferential clamp and centering ring form the vacuum seal between the connecting flanges (please see top right figure – click to enlarge). The centering ring contains a rubber elastomer o-ring. The standard sizes for quick flange fittings are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50, respectively. They are made of corrosive-resistant stainless steel.

What kind of Stainless Steel KF Vacuum Flange we can offer?

Stainless Steel KF Vacuum Flange Applications

Stainless Steel Turned Parts are used to produce a variety of parts in the medical industry, robotics, food, and beverage industry, aerospace, and any industry that requires high-strength applications. Stainless steel is an ideal material for applications such as:

- Medical instruments

- Home appliances

- Storage containers

- Pressure tanks

- Machine parts

- Vacuum and pressure vessels

Stainless steel provides excellent machinability, and outstanding uniformity, and is corrosion and oxidation resistant, leading to longer product life and lower total cost of machined parts.

Benefits of Stainless Steel KF Vacuum Flange

- Processed for improved machinability

- Outstanding uniformity

- Faster machining speeds

- Longer tool life

- Improved part surface quality

- Corrosion resistant

- The lower total cost of machined parts

3 featured things before we design and produce Stainless Steel KF Vacuum Flange

1. Material Name

- Stainless steel 304/304L ,1.4301/1.4307

- Stainless steel 316/316L 1.4401/1.4404

2. Mechanical & Chemical Properties

- KF, CF to NPT, BSPT, GFS, Hikelok tube fitting

- copper seal vacuum range: ≥ 10–12 Torr

- Elastomeric seal vacuum range: ≥ 10–8 Torr

- Copper seal working temperature from -325℉ to 842°F (-200℃ to 450℃)

- Elastomeric seal working temperature from -4°F to 302°F (-20℃ to 150℃)

What to keep in mind when using Stainless Steel KF Vacuum Flange

There are several advantages to the use of ISO components.

Since component dimensions are standardized, elbows, tees, crosses, or valves for a given size may be interchanged.

These KF-50 90-degree elbow vacuum fittings follow ISO-KF standards and have a flange size of NW-50.

They are commonly used to build fireline vacuum plumbing and process systems.

They are often called quick flange fittings because they are quick to assemble.

A circumferential clamp and centering ring form the vacuum seal between the connecting flanges (please see top right figure – click to enlarge).

The centering ring contains a rubber elastomer o-ring.

The standard sizes for quick flange fittings are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50, respectively.

They are made of corrosive-resistant stainless steel.

Possibility of replacement by other materials

It is not an easy task to find a material that would not be inferior to stainless steel in terms of aesthetic qualities, strength, and corrosion resistance. Carmakers usually use carbon fiber, while manufacturers of equipment for restaurants – use alloys of non-ferrous metals. We recommend you consider making Stainless Steel Turned Parts from less expensive grades of steel or aluminum, together with the subsequent anodizing.

Any more interesting ideas, please feel free to share them with us. Please send your designs or drawings directly to our mailbox: [email protected].