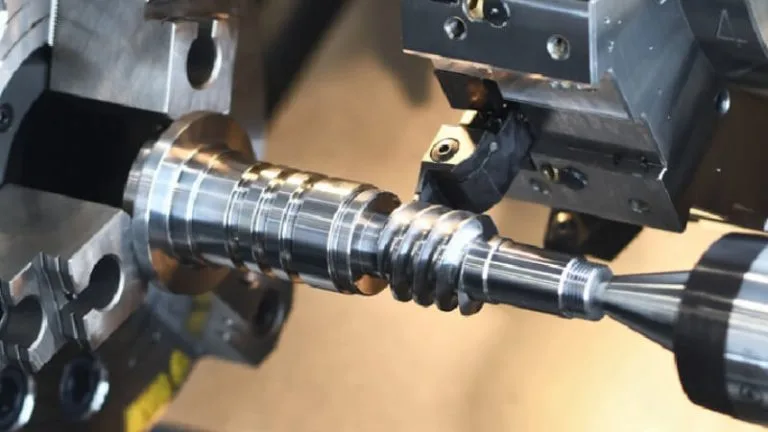

Overview

Automotive motor shafts

Ningbo FRIMA can produce a wide range of automotive motor shafts for every application including motor shafts, and industrial and automotive applications. These include round shafts, square shafts, stepped shafts, splined shafts, helical shafts, gear shafts, D-key shafts, and threaded shafts.

Bring us your ideas and we’ll help you get your shaft application off the ground.

Learn about our products

- Offerings Overview

- Manufacturing Processes

- Quality Systems

- Professional service

Overview Automotive motor shafts from Ningbo FRIMA:

Ningbo FRIMA has audited, qualified, and worked with IATF and ISO-certified shaft factories for over 15 years. We are dedicated to managing your custom shaft project on-site and delivering parts to you at lower prices but the same quality as a domestic supplier.

- Custom shafts

- Round cross-section

- Splined Shafts

- Square/rectangular

- Cam Shafts

- D-shaped key end

- Stepped Shafts

- Slotted end

- Helical Shafts

- Geared Shafts

1. Material

Common material: 40Cr/35C/GB45/70Cr/42CrMo

Other materials: Stainless steel, copper, brass, carbon steel, aluminum (according to customer’s requirement)

2. Process

CNC rough turning, Quench+Temper, precision machining, grinding

- external diameter:5.0-15.0mm

- overall length:50-200mm

- tolerance:±0.005

- surface hardness: HRC 20- HRC 57

- There is an ISO standard for automotive motor shafts ISO 496:1973.

3. Radii

Turned outside corners will typically include a 0.005 in. chamfer.

Minimum hole size:

- Minimum on-axis and axial: 0.04 in. (1mm)

- Minimum radial: 0.08 in. (0.5mm), 0.04 in (0.5mm) for aluminum and brass

4. Grooves:

- Minimum OD groove width: 0.047 in. (1.2mm)

- Minimum OD groove width for aluminum and brass:0.019 in (0.5mm)

- Maximum OD groove depth: 0.95 in. (24.1mm)—varies with a groove width

What equipment to manufacture Automotive motor shafts:

Ningbo FRIMA brings together advanced manufacturing equipment such as CNC and lathes from Japan and Taiwanese centerless grinding machines, gear hobbing machines, straightening and cutting machines, sphere lapping machines, end grinders, cylindrical grinders, rolling grinders, and ultrasonic cleaning and polishing machines. These are key to manufacturing custom shafts and motor shafts.

Quality control systems for Automotive motor shafts :

High-precision manufacturing and laboratory test equipment provide for consistency and accuracy of standard and custom shafts.

Based on ISO9001:2015 & IATF 16949:2009 quality requirements, the main control plan is as below:

- Raw Material Quality Control: Chemical Composition Analysis, Mechanical Performance Test, ROHS, and Mechanical Dimension Check

- Production Process Quality Control: Full-size inspection for the 1st part, Critical size process inspection, SPC process monitoring

- Lab ability: CMM, OGP, XRF, Roughness meter, Profiler, Automatic optical inspector

- Quality system: ISO9001, IATF 16949, ISO14001

- Eco-Friendly: ROHS, Reach.

We are experts in providing Level 3 PPAP documentation for custom shafts and motor shafts, including:

- Capability studies

- Control plans

- Gage R&Rs

- Failure Modes and Effects Analysis (FMEA)

- Custom statistical analysis

5. CNC Precision Machining Automotive Motor shafts Standards

| CNC Machining Standards (DIN ISO 2768-1(1991-06) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tolerance class | tolerance(mm) | |||||||||||||

| Metal (ISO 2768-F) | Plastic (ISO 2768-F) | |||||||||||||

| 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

Show All

6. General Tolerances For Shape And Position

| General tolerances for shape and position (DIN ISO 2768-2(1991-04) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tolerance class | tolerance(mm) | |||||||||||||

| Straightness and Flatness | Verticality | Symmetry | ||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.02 | ±0.05 | ±0.1 | ±0.2 | ±0.3 | ±0.4 | ±0.2 | ±0.3 | ±0.4 | ±0.5 | ±0.5 | |||

Show All

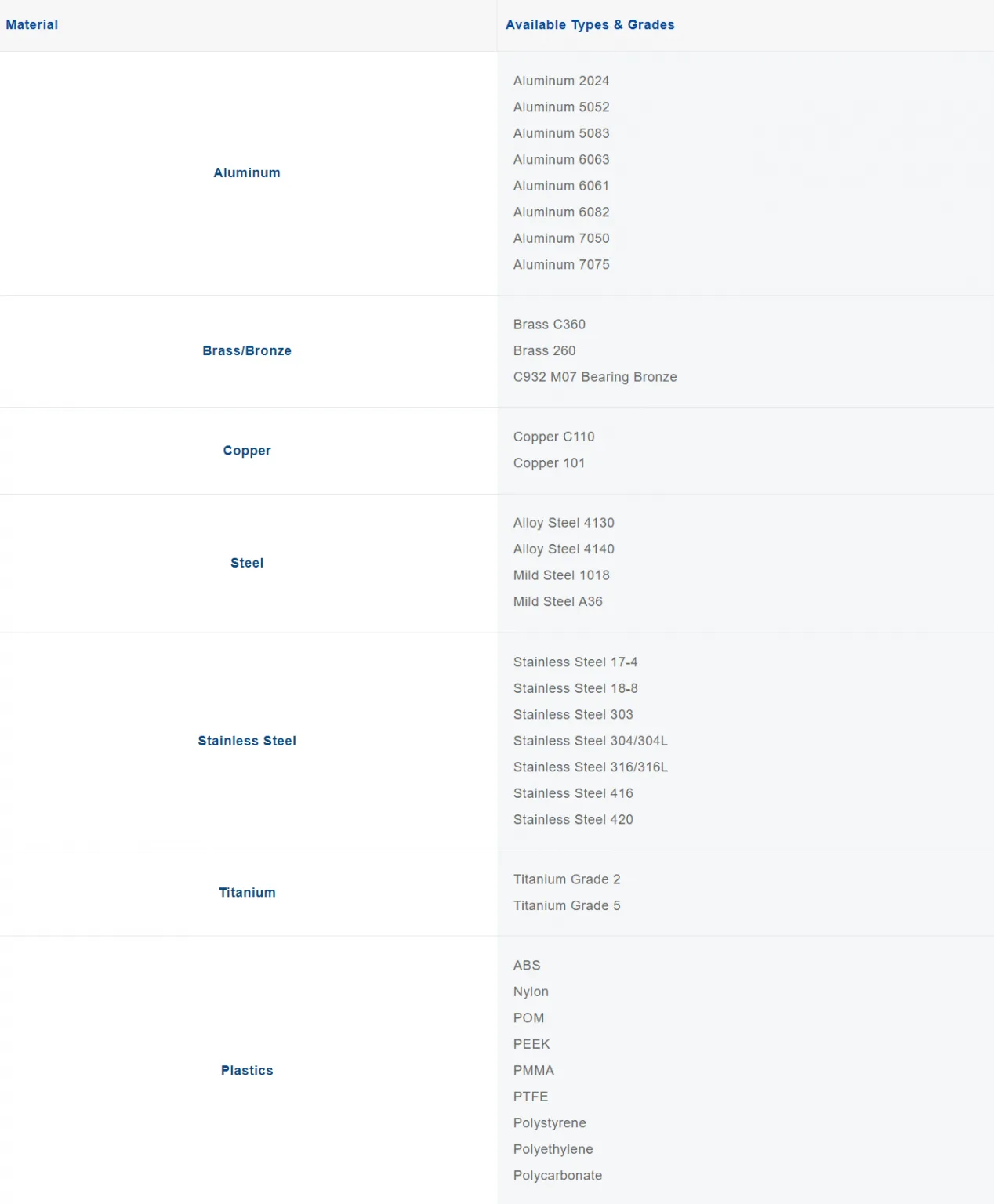

Materials Used for Automotive Motor Shaft

automotive motor shafts can be applied to various materials, including metal, plastic, and wood. Different lathes are needed for turning metal and wood. According to the types of machined part materials, certain maintenance and safety precautions may be required for the lathe.

Here are some common materials for precision machining automotive parts below. If the material you required is not listed in the table, please contact us.

Show All

Surface Finish at FRIMA – Process for Automotive Motor Shafts

Here is a wide selection of metal surface finishing services of your choice for the machined automotive motor shafts to improve the part appearance, surface smoothness, corrosion resistance, and other characteristics.

| As machined | Description |

|---|---|

| As machined | Standard finish with a surface roughness of 1.6 μm (126 μin). |

| Smoothing | The standard smoothing surface roughness (Ra) is 0.8 μm (63 μin). |

| Painting | Spraying paint, pigment, or color to a solid surface as a colored protective layer. |

| Passivation | Remove ferrous contaminants or use a light coat of protective material to create a shell. |

| Powder Coating | A functional and decorative finish that is applied as a free-flowing, dry powder. |

| Anodizing | Type II (anodizing color or clear) or Type III (anodizing hard coat) |

| Polishing | Produce a smooth and shiny surface. |

| Black Oxide | Formed a black conversion coating on metal parts. |

| Bead Blasting | Removing surface deposits by applying fine glass beads at high pressure. |

| Abrasive Blasting/Sandblasting | Smoothing and cleaning a hard surface by forcing solid particles across that surface. |

| Electroplating/Plating | Form a thin coherent metal coating on an electrode. |

| Brushing | Polishing the metal with grit results in a unidirectional satin finish. |

| Chromate Conversion oating | Increase the corrosion resistance while maintaining conductive properties |

Show All

Service at FRIMA Automotive motor shafts:

Professional Custom Services:

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business.

FRIMA utilizes several different shipping methods that are detailed below:

For Samples/Small Q’ty: By Express Services or Air Fright.

For Formal Order: By Sea or by air according to your requirement.

- One-Stop solution from idea to product/ODM&OEM acceptable

- Individual research and sourcing/purchasing tasks

- Individual supplier management/development, on-site quality check projects

- Muti-varieties/small batch/customization/trial orders are acceptable

- Flexibility on quantity/Quick samples

- Forecast and raw material preparation in advance are negotiable

- Quick quotes and quick responses

If you are looking for a reliable machinery product partner, you can rely on FRIMA. Work with us and let us help you grow your business using our customizable and affordable products.