Precision Machining Service: Elevating Accuracy and Quality

We are dedicated to providing a Precision Machining Service that goes beyond industry benchmarks. Our steadfast commitment to precision guarantees that each component produced through our machining processes meets the highest standards of tolerances, ensuring unparalleled quality and performance.

- home

- Precision Machining

Precision Machining Basics

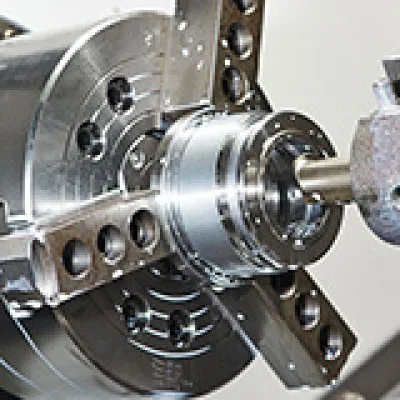

Precision machining is a fundamental manufacturing process that involves the removal of material from a workpiece with the goal of achieving exacting dimensions and tight tolerances. Utilizing advanced machinery and cutting-edge technology, precision machining allows for the creation of intricate components with exceptional accuracy. This method is crucial in various industries where precision is paramount, including aerospace, medical, automotive, and electronics. The precision machining process encompasses techniques such as CNC milling, CNC turning, grinding, and EDM machining, each contributing to the production of components that adhere to stringent specifications.

PRECISION MACHINING CAPABILITIES

FRIMA is equipped with state-of-the-art CNC machines and precision tools, we ensure optimal accuracy and repeatability in our machining processes. Our precision machining services exhibit extensive materials expertise, covering a diverse range that includes metals, plastics, and composites, providing versatility to meet the unique needs of various industries.

Equipment

CNC Control Capabilities

Vertical and Horizontal Machining Centers5-Axis Mills

vertical Mills

Drill Presses

Vertical and Horizontal Machining Centers5-Axis Mills

vertical Mills

Drill Presses

Raw Material Forms

Coil

Sheet

Plate

Sheet

Plate

Bar

Round

Extrusions

Round

Extrusions

Materials

Aluminum

Cold Rolled Steel

Hot Rolled Steel

stainless steel

Plastics

Cold Rolled Steel

Hot Rolled Steel

stainless steel

Plastics

Brass

Copper

Galvanized

Reinforced Epoxy(FR4)

Copper

Galvanized

Reinforced Epoxy(FR4)

Finishes

Graining

Plating

Powder Coating

Plating

Powder Coating

Wet Paint

Silk Screening

Silk Screening

Plating

Conversion Coating (Alodine)

Zinc

Nickel

Anodize

Zinc

Nickel

Anodize

Tin

Gold

silver

Passivation

Gold

silver

Passivation

Part Length

up to 24 in

Part Width

up to 24 in

Part Height

up to 12 in

Tolerance

±.001 in

±.0254 mm

±.0254 mm

value Engineering

Manufacturability

Cost Reduction

Cost Reduction

Production Volume

Prototype to Production

Production Lead Times

6 weeks

Machining Processes

Milling

Boring

Countersinking

Boring

Countersinking

Drilling

Tapping

Counterboring

Tapping

Counterboring

Secondary Processes

Heat Treating

welding

Spot welding

wet Painting

Powder coating

welding

Spot welding

wet Painting

Powder coating

Plating

Silk Screening

Hardware Installation

Mechanical Assembly

Precision Liquid Dispensing (FIP)

Silk Screening

Hardware Installation

Mechanical Assembly

Precision Liquid Dispensing (FIP)

ADDITIONAL INFORMATION

Industry Focus

Military and Defense

Medical

Lighting

Electronics

Medical

Lighting

Electronics

Energy

Communications

Transportation

Communications

Transportation

Intended Applications

Computer Chassis

Testing Equipment

Rack Solutions

Testing Equipment

Rack Solutions

lndustry Standards

AS910OD Certified

ANSI

ASTM

ITAR Compliance

ANSI

ASTM

ITAR Compliance

ISO 9001:2015 Certified

Mil-Spec

RoHS

Reach

Mil-Spec

RoHS

Reach

Efficiency

Kanban

Lean Manufacturing

Just ln Time (JIT)

Lean Manufacturing

Just ln Time (JIT)

ESMI

ERP

ERP

File Formats

SolidWorks

AutoCad

DraftSight

AutoCad

DraftSight

.STEPI.STP

.IGES

.DFX.DwG

.IGES

.DFX.DwG

Precision machining is a manufacturing process in which machines are used to create parts with high levels of accuracy. The machines used for precision machining are typically CNC (computer numerical control) machines, which are controlled by a computer program. The program tells the machine what cuts to make and how to make them, in order to create the desired part.

Precision machining is used in a variety of industries, including aerospace, medical, and automotive. It is often used to create parts that require tight tolerances, such as engine parts, medical implants, and aerospace components.

What factors should you consider when choosing a precision machining service

There are many factors to consider when choosing a precision machining service. Here are some of the most important factors to keep in mind.

Type of machining you need

There are many different types of machining, from complex 4-axis machining to simple 3-axis machining. Make sure you choose a service that offers the type of machining you need.

Size of the workpiece

The size of the workpiece will dictate the size of the machine needed to machining it. Make sure you choose a service that has the appropriate sized machines for your needs.

The tolerances

Precision machining is all about achieving tight tolerances. Make sure you choose a service that has the experience and capability to meet your tolerance requirements.

The turnaround time

The turnaround time for a precision machining project will vary depending on the complexity of the project.

Why Choose FRIMA Precision Machining Services

We can manage any production volume, from prototypes to mass production.

The parts can be machined to the same close tolerances, repeatedly, from part to part.

We measure and cut most precision parts with exact specifications.

We have various CNC machining and precision machining facilities and setups to ensure capability.

Our high flexibility allows us to tackle intricate complex designs and take them to

market.

FRIMA adheres to a wide range of industry standards, including QMS TS 16949, ASTM, ANSI and those compatible with MRP/ERP, and is certified to ISO 9001. As a supporter of lean manufacturing production practices, FRIMA can work with CAD files in AutoCAD, SolidWorks, and Pro/E formats.

FRIMA’s range of equipment and their team’s vast knowledge and expertise has earned them a well-deserved global reputation for precision machining. Contact them for more information, or see the table below.

Why Choose FRIMA Precision Machining Services

● We can manage any production volume, from prototypes to mass production.

● The parts can be machined to the same close tolerances, repeatedly, from part to part.

● We measure and cut most precision parts with exact specifications.

● We have various CNC machining and precision machining facilities and setups to ensure capability.

● Our high flexibility allows us to tackle intricate complex designs and take them to market.

FRIMA adheres to a wide range of industry standards, including QMS TS 16949, ASTM, ANSI and those compatible with MRP/ERP, and is certified to ISO 9001. As a supporter of lean manufacturing production practices, FRIMA can work with CAD files in AutoCAD, SolidWorks, and Pro/E formats.

FRIMA’s range of equipment and their team’s vast knowledge and expertise has earned them a well-deserved global reputation for precision machining. Contact them for more information, or see the table below.

● The parts can be machined to the same close tolerances, repeatedly, from part to part.

● We measure and cut most precision parts with exact specifications.

● We have various CNC machining and precision machining facilities and setups to ensure capability.

● Our high flexibility allows us to tackle intricate complex designs and take them to market.

FRIMA adheres to a wide range of industry standards, including QMS TS 16949, ASTM, ANSI and those compatible with MRP/ERP, and is certified to ISO 9001. As a supporter of lean manufacturing production practices, FRIMA can work with CAD files in AutoCAD, SolidWorks, and Pro/E formats.

FRIMA’s range of equipment and their team’s vast knowledge and expertise has earned them a well-deserved global reputation for precision machining. Contact them for more information, or see the table below.

Frequently Asked Questions (FAQ) about Precision Machining

What industries benefit from your Precision Machining Service?

We serve a diverse range of industries, including aerospace, automotive, medical, electronics, and more, where precision components are crucial.

Can you handle both prototyping and large-scale production?

Absolutely. Our precision machining services are tailored to accommodate both prototyping and large-scale production, providing flexibility for varying project needs.

What materials can you work with in your precision machining processes?

Our capabilities extend across metals, plastics, and composites. We work with materials such as aluminum, stainless steel, titanium, and various engineering plastics.

How do you ensure quality in your precision machining processes?

Rigorous quality control measures are integrated into every step of our machining processes. From initial material inspection to final product evaluation, we uphold the highest standards.

What sets your Precision Machining Service apart from others in the industry?

FRIMA Parts stands out with its dedication to precision, advanced technology, skilled craftsmanship, and the ability to provide customized solutions for diverse client needs. Our commitment to excellence is reflected in every machined component we produce.