CNC Turning Service

Discover excellence with FRIMA Parts – your go-to destination for on-demand custom CNC machining services that redefine industry standards. What sets us apart is our unwavering dedication to precision, unparalleled quality, and utmost client satisfaction.

- home

- cnc turning

CNC Turning Basic

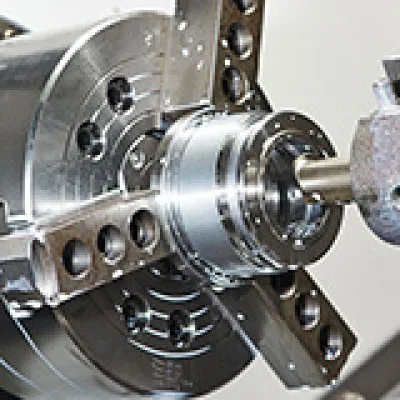

CNC turning, an abbreviation for computer numerical control turning, is a highly automated machining technique focused on crafting cylindrical parts. The process involves rotating a workpiece while a cutting tool, typically made of carbide or high-speed steel, precisely shapes the material according to programmed instructions. Key components, such as the spindle, CNC controller, and optional tailstock, work in tandem to ensure efficiency and accuracy in the production of components.

This meticulous process unfolds through essential steps, starting with securely mounting the workpiece on the spindle for precise alignment. Tool selection, programming specific instructions, and the actual machining operation follow, allowing the CNC turning machine to rotate the workpiece while the cutting tool sculpts it into the desired form. The versatility of CNC turning shines as it adapts to various materials, delivering high precision and efficiency in crafting an extensive range of cylindrical parts.

Connect with Us – Your Gateway to Innovative Solutions

We’re eager to engage with you and explore the possibilities that lie ahead. Our team of experts boasts a proven track record in delivering groundbreaking solutions across the entire spectrum of product development – from the initial stages of design to the final phases of production.

High Standards in CNC Turning at FRIMA Parts

We produce your bespoke components in accordance with rigorous manufacturing standards, ensuring strict adherence to the Hubs Standard for both parts and processes. Our commitment to quality is reflected in a comprehensive verification process, detailed in the inspection report provided with each order.

Precision is our Priority

At FRIMA Parts, precision is the cornerstone of our CNC turning services. Employing state-of-the-art equipment and meticulous craftsmanship, we prioritize accuracy at every stage, ensuring that each component meets or surpasses the most stringent tolerances.

Cutting-Edge Technology and Skilled Craftsmanship

Staying ahead in technology and expertise defines our approach. Our investment in cutting-edge CNC turning machines, coupled with a team of highly skilled engineers and technicians, guarantees the production of components with exceptional precision and efficiency.

Rigorous Quality Control and Adherence to Regulations

Quality is not just a goal; it’s a standard we uphold rigorously. From thorough material inspection to final product evaluation, our CNC turning processes maintain strict quality control measures. Moreover, our adherence to industry regulations ensures that components not only meet client specifications but also align with the highest industry benchmarks.

Available Materials for CNC Turning

CNC turning is capable of working with a variety of materials to create precise cylindrical components. The choice of material depends on the specific requirements of the project. Understanding the properties of each material is crucial in selecting the most suitable option for a given CNC turning project. CNC machining services often offer a range of materials to accommodate various design and performance requirements.

Metals

Steel

Suitable for a wide range of applications, offering strength and durability.

Aluminum

Lightweight and corrosion-resistant, commonly used in aerospace and automotive applications.

Stainless Steel

Known for its corrosion resistance and strength, ideal for parts requiring durability.

Brass

Provides a combination of corrosion resistance, durability, and an attractive appearance.

Copper

Known for its excellent electrical conductivity, often used in electrical components.

Plastics

ABS (Acrylonitrile Butadiene Styrene)

A versatile thermoplastic known for its strength and impact resistance.

Acrylic (PMMA)

Transparent and lightweight, commonly used for optical applications.

Nylon

Offers strength, flexibility, and resistance to abrasion, suitable for various applications.

PEEK (Polyether Ether Ketone)

A high-performance thermoplastic known for its mechanical and chemical resistance.

Delrin (Polyoxymethylene – POM)

High-strength, low-friction plastic, suitable for precision parts.

Other Materials

Titanium

Known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility.

Composite Materials

Such as carbon fiber reinforced polymers, offering a combination of strength and lightweight properties.

Advantages of CNC Turning

CNC turning offers a combination of precision, efficiency, and versatility, making it a preferred choice in various industries for the production of high-quality cylindrical components.

Tight Tolerances

CNC turning provides high precision, allowing for the creation of components with tight tolerances. This accuracy is crucial in industries where precision is paramount.

Material Compatibility

CNC turning is versatile and compatible with various materials, including metals, plastics, and composite materials. This versatility enables the production of a wide range of cylindrical parts.

Intricate Designs

The process excels at creating components with complex geometries. CNC turning machines can produce intricate shapes and features that may be challenging with traditional machining methods.

Economies of Scale

While initial setup costs may be involved, CNC turning becomes highly cost-effective for large production volumes. The efficiency of the process and reduced labor costs contribute to overall cost savings.

Faster Production

The automated nature of CNC turning allows for faster production cycles, resulting in shorter lead times for the completion of projects.

Automated Operation

The process is highly automated, reducing the need for manual intervention. This automation leads to consistent and efficient production, making CNC turning ideal for large-scale manufacturing.

Quick Changeovers

CNC turning machines allow for quick and efficient changeovers between different production runs. This reduces setup time, making it a cost-effective solution for projects with varying requirements.

Repeatable Results

CNC turning ensures consistent and repeatable results across multiple parts. This consistency is crucial for maintaining quality standards in large production runs.

Cost-Effective for Large Runs:

Optimized Material Usage

CNC turning minimizes material waste by precisely removing only the necessary material to create the part. This is especially beneficial when working with expensive materials.

Prototyping Capabilities

CNC turning is not only suitable for large-scale production but also for prototyping. This versatility allows for the efficient testing and refinement of designs.

Frequently Asked Questions (FAQ) about CNC Turning

What tolerances can be achieved with CNC turning?

CNC turning is known for its high precision, and tolerances as tight as a few thousandths of an inch can be achieved, depending on the material and the specific requirements of the project.

Is CNC turning suitable for prototyping?

Yes, CNC turning is suitable for both prototyping and large-scale production. It offers the flexibility to create prototypes quickly and accurately, allowing for testing and refinement of designs.

How does the CNC turning process work?

The process begins with mounting a workpiece on a rotating spindle. A cutting tool, guided by computer-programmed instructions, removes material from the workpiece to create the desired shape. The CNC machine controls the tool’s movements and the rotation of the workpiece.

What file formats are compatible with CNC turning?

CNC turning machines typically work with 3D computer-aided design (CAD) models in formats such as .STL, .STEP, and .IGES. These files provide the necessary instructions for the CNC machine to create the part.

Can CNC turning be used for intricate designs?

Yes, CNC turning is capable of producing intricate and complex designs. The precision and versatility of the process make it suitable for creating detailed features and shapes.

What is the typical lead time for CNC turning projects?

Lead times for CNC turning projects vary based on factors such as project complexity, quantity, and material. FRIMA Parts is committed to providing realistic timelines and efficient project completion.

Is CNC turning cost-effective for large production runs?

Yes, CNC turning becomes cost-effective for large production runs due to its automated nature, which reduces labor costs and ensures consistent quality across a high volume of components.

What quality checks are performed during CNC turning?

Throughout the CNC turning process, quality checks are conducted to ensure dimensions and tolerances are within specifications. Some CNC machines are equipped with probes for automated measurements, contributing to the overall quality assurance of the machined parts.