Overview

Stainless Steel Machined Flange Cover

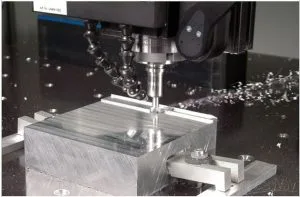

Stainless Steel Machined Flange Cover is a component or assembly that has been manufactured by machining. Stainless steel is a hard and viscous material. In terms of processing complexity, it is about three times superior to softer metals, like aluminum. This means that in order to make a part from stainless steel, the machine must make three times as many passes. And the tool, which performs processing, wears out faster. But this is not a problem for us.

Stainless steel 304 is the most common stainless steel. It is essentially non-magnetic steel and it is less electrically and thermally conductive than carbon steel. It is wildly used because it is easily formed in various shapes. It is machinable and weldable. Other names for this steel are A2 stainless steel, 18/8 stainless steel, UNS S30400, and 1.4301. 304L stainless steel is the low-carbon version of stainless steel 304.

What kind of Stainless Steel Machined Flange Cover we can offer?

Stainless Steel Machined Flange Cover Applications

CNC machining of stainless steel is used to produce a variety of parts in the medical industry, robotics, food and beverage industry, aerospace, and any industry that requires high-strength applications. Stainless steel is an ideal material for applications such as:

- Medical instruments

- Home appliances

- Storage containers

- Pressure tanks

- Automotive parts

- Machine parts

- Parts for tractors

- Heavy construction equipment

- Vacuum and pressure vessels

- Stainless Steel Machined Flange Cover

- Bolts and nuts

- Shafts

- Screws

- Gears

Stainless steel provides excellent machinability, and outstanding uniformity, and is corrosion and oxidation resistant, leading to longer product life and lower total cost of machined parts.

Benefits of Stainless Steel Machined Flange Cover

- Processed for improved machinability

- Outstanding uniformity

- Faster machining speeds

- Longer tool life

- Improved part surface quality

- Corrosion resistant

- The lower total cost of machined parts

3 featured things before we design and produce Stainless Steel Machined Flange Cover

1. Material Name

- Stainless steel 304/304L ,1.4301/1.4307

- Alternative names X5CrNi18-10, 1.4301

2. Mechanical & Chemical Properties

- Chromium content: 16-20.0%

- Nickel content: 6-15%

- Molybdenum[5] content: 2-4%

- Ultimate tensile strength: 520-600 MPa

- Typical max Hardness: 180 HB

- Yield strength: 210-250 MPa

- Elongation at break: 43-45 %

- Electrical resistivity: 65 – 70 μΩ*cm

- Maximum service temperature: 750 – 925 °C

- Thermal expansion coefficient: 10.3 – 12 10^-6/ºC

- Thermal conductivity: 29.3 – 31.7 W/(m⋅°C)

- Corrosion resistance: Good

- Magnetism: No

- UV resistance: Excellent

3. Post treatments

- Post-Processing: Annealing & Cold working

- Anodizing compatibility: Not suitable

- Weldability: Excellent

What to keep in mind when designing Stainless Steel Machined Flange Cover

Most of the equipment for the food and processing industries is made with Stainless Steel Machined Flange Cover. This is really excellent material, both visually and from an engineering point of view. For a long time, it is being used in the manufacturing of refrigerators, dishwashers, deep fryers, etc. Among the main benefits of this material are high corrosion resistance, durability, and compliance with hygienic requirements. However, engineers who use it also can face unique challenges. We will tell you about them.

Corrosion resistance strongly depends on the type of stainless steel

303 stainless steel is best at handling and gives a significant price benefit due to the fact that its processing is less time-consuming and it affects the wearing of tools a bit less than other materials.

Most branches of the food industry use steel 301 and 304 series. These are the most common types of stainless steel. Due to high demand, their prices are constantly fluctuating. During the year alone, the cost can rise or fall up to 25%. This is caused by fluctuations in world prices for nickel, which is one of the main components of stainless steel alloys.

Take into account the class of corrosion resistance and other qualities of the metal. And also, speaking about the price of the material, it is always better to pay attention to the actual purposes of the purchase. For example, if the parts are going to be used only for decoration, then there is no point in using the material from the high-price segment, better to use a less expensive one.

Problems of connecting stainless steel 304 machined parts

Stainless steel welding is a complex process. And when it comes to a combination of parts made of different types of stainless steel, a number of certain issues tend to appear. It is quite difficult to weld any part with another and preserve its original properties. Only highly qualified workers need to be involved. Otherwise, you may choose to use more expensive technology, such as robotic laser welding.

The biggest problem here is to provide sufficient resistance to corrosion of the weld. Therefore, it is better to include other types of connections to the project at its development stage. A threaded connection is most often used with stainless steel. Please note that the polished surface of stainless steel, despite making it beautiful and durable, significantly complicates the process of connecting with other parts.

That is why most of the manufacturers of equipment for the food industry deliberately design some elements that should provide access to internal mechanisms, and prefer ordinary carbon steel to stainless steel.

Possibility of replacement by other materials

It is not an easy task to find a material that would not be inferior to stainless steel in terms of aesthetic qualities, strength, and corrosion resistance. Carmakers usually use carbon fiber, while manufacturers of equipment for restaurants – alloys of non-ferrous metals. We recommend you consider making parts from less expensive grades of steel or aluminum, together with the subsequent anodizing.

Any more interesting ideas, please feel free to share them with us. Please send your designs or drawings directly to our mailbox: [email protected].